Discover the benefits of drone for warehouses to increase operational efficiency in production facilities.

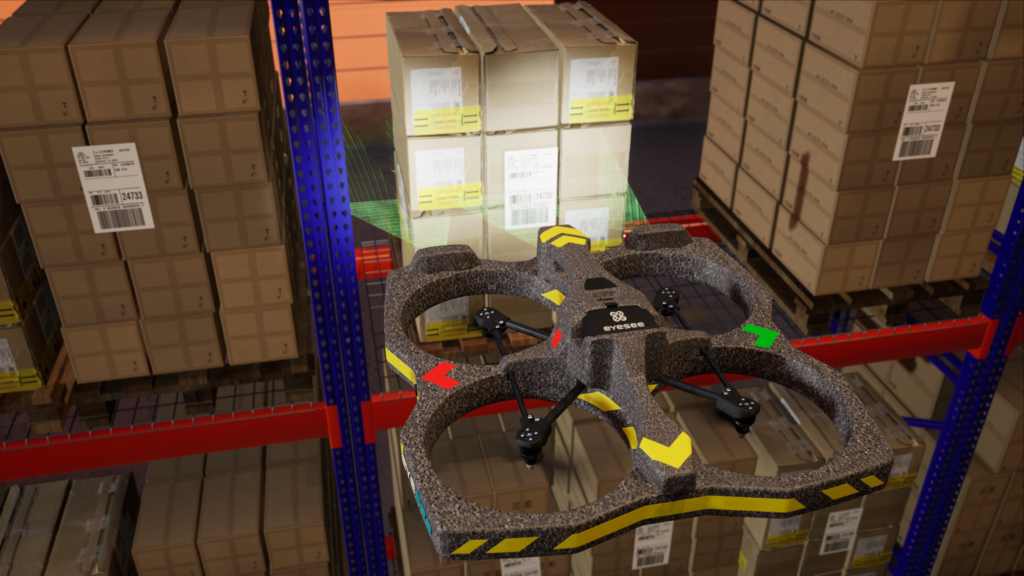

EYESEE is an inventory drone solution for logistics warehouses organized in pallets.

The solution improves inventory processes by meeting the needs of logisticians and manufacturers.

Inventory is a task that requires many resources: financial, material and human.

Furthermore, regulations require companies to take an inventory of their stock at least once a year.

Manual inventory

Inventory by drone

10 persons & more

Only 1 person to supervise the flight of the drone

The use of 1 or more scissors lifts (owned or rented)

No scissors lift

1 visit/years per location

50 locations per hour

4 visits/years per location

Up to 500 locations per hour

60 to 90 seconds per location

6 to 10 seconds per location

Thanks to the time savings generated by the use of the EYESEE Solution, companies can switch to cycle count inventory while reducing their inventory costs.

The importance of accurate inventory tracking in the warehouse should not be underestimated as errors generate direct operational costs.

It is important that all goods in the warehouse are accurately accounted for so that customer orders can be delivered on time.

The drone for warehouses EYESEE allows faster and more frequent inventories to identify potential errors.

Thanks to the different modes that can be configured, you can create inventory missions:

Employee safety in the warehouse is a major issue for logisticians. As soon as an operator has to access a stock at height and uses a scissor lift, he increases his risk of falling.

Thanks to the drone for warehouses, it has become possible to eliminate the use of scissors lift to control stocks, and thus significantly reduce the risks associated with working at height.

With EYESEE, only one person is needed to inventory your entire inventory. No more need for cradles. The solution also integrates many safety functions. In case of structural defects, damaged pallets or pierced packages, the operator can declare a point of interest during the flight.

With reliable inventory counts, orders will be in compliance and shipped as expected by the customer. The impact of accurate inventory tracking is not limited to cost savings and increased efficiency.

The ability to provide optimal customer service depends on having the right products in the right place at the right time.

To achieve this goal requires frequent and accurate inventory counts.

With the EYESEE solution, identify inventory errors upstream before they become costly downstream problems.

In fact, finished goods warehouses adjacent to or near production sites often receive, store and reship goods in a full handling unit format. The main reason for this is that these pallets are destined for distributors or other depots where they will be broken down and shipped in packages or reassembled depending on the destination. These warehouses therefore have a proportion of racked reserves close to 100%. Most of the time, there is no picking activity, which ensures that the pallets made up, filmed and labeled with the quantity are compliant and perfectly readable by the drone. The production sites thus have all the criteria to benefit 100% from the advantages offered by EYESEE.

How much time do you spend controlling your finished goods inventory?

[Watch our latest EYESEE inventory robot embedded video

Wondering how your inventory mission is done with EYESEE?

We reveal all in the video below. Get on board during a supervision of an inventory mission with EYESEE. The drone inventory solution will have no more secrets for you!

You are here in the interface of the control tablet.

Settings of EYESEE Tablet :

Beginning of the mission

You are probably wondering “How does EYESEE Drone know which locations to scan?

The answer is very simple: Beforehand, the dimensions of the aisle faces in the warehouse were entered. Mapping is a 2D representation of an aisle face in a warehouse. By indicating:

EYESEE Drone knows at any time in front of which location it is.

Data acquisition:

EYESEE detects full and empty locations, and takes pictures of each location.

00:26: When EYESEE Drone detects and scans the barcode on the pallet, the code appears in green at the bottom of the control screen.

02:22: If the location is empty. The word “empty” appears at the bottom of the control screen.

03:00: When the drone does not detect any barcode, but the location is full, a ” no scan ” appears at the bottom of the control screen.

There are different reasons for this:

Figure above: Point of Interest (POI) declaration menu

2. The barcode is not readable. EYESEE Drone did not succeed in reading it. In this case, the operator can ask EYESEE Drone to restart the bar code acquisition at this location, or without operator intervention if the automatic mode is activated.

3. A dynamic storage: the pallet is on 2 locations at the same time, and only one barcode is present. The post mission data processing will correct the error.

End of the mission:

Time saving:

The timer indicates the duration of the mission.

In the mission presented in the video, EYESEE Drone inventoried a side of 36 locations in an AFTRAL school in 04min25, that is to say an average of 7 seconds per location, with a vertical speed configured on “intermediate” (60cm/s).

Do not hesitate to react in comments!

Watch the replay of our webinar, and switch to cycle count inventory with the drone warehouse inventory.

Find out how the drone logistics inventory allows you to increase productivity in your warehouse.

The program:

EYESEE is a warehouse drone inventory. This solution allows one person to scan an average of 400 pallet locations per hour.

Thanks to these different modes of use (with expected, blind, spot location), EYESEE is a powerful tool to switch to cycle count inventory.

Many companies chose EYESEE for the inventory of their warehouses. This is especially the case of L’ORÉAL.

Before EYESEE, L’ORÉAL carried out manual inventories with :

Thanks to the inventory drone solution, L’ORÉAL has switched to a cycle count inventory of 1 to 2 hours per week. This allows the company to check each location more than 4 times a year and thus reduce stock errors (with an accuracy of 99.8% and continuous opening of the logistics centre without any interruption of activities).

Are you interested in our drone inventory solution?

Check your eligibility in 2 minutes and get a first estimate of the productivity in your warehouse.

EYESEE in your warehouse in 4 steps:

You will work under the responsibility of the Product Director of the company and in close coordination with the people in charge of the development of the applications. You will be autonomous in your function of drone deployment manager and will join the multidisciplinary team of Darwin Drones.

After training on the company’s solutions, offers and processes, your missions will be:

Minimum training bachelor + 2

You have at least 1 year of experience in the field of logistics:

Your bonus asset:

You know the stakes and processes of the supply chain of companies and the tools used (software and hardware).

You already have experience in the deployment of technological products or services.

Salary: depending on experience.

Localisation: Grenoble – with frequent travel in France & Europe.

Created in 2021 and based in Grenoble, France, Darwin Drones specializes in the development and marketing of industrial logistics automation solutions, particularly by drone.

Darwin Drones also provides services associated with this activity. The company is dedicated to the marketing, support, and software development of the EYESEE solution for the logistics market.

The EYESEE drone inventory solution was designed to simplify and secure the control of stocks and locations of goods stored on pallets in warehouses. It can read any barcodes from a few centimeters to more than 10 meters high. The solution is equipped with many sensors (ZEBRA scanners, camera, geolocation system, autopilot and motion detectors) that allow it to fly autonomously in each logistics aisle.

Our expertise in mechanics, electronics, and software has already seduced many industrialists and logisticians such as L’Oréal Cosmétique Active, DHL, Schneider Electric, Renault Trucks & Log’s.

The drone-based inventory solution, designed and patented by Hardis Group and co-developed with Squadrone System since 2015, will now be marketed, developed, and operated by Darwin Drones, a new company based in Grenoble. The entity will build on this local innovation success story and work to accelerate take-up of the solution in France and worldwide.

Grenoble, March 30, 2022 – Hardis Group, a consulting firm, digital services company and software editor of the Reflex logistics execution software suite, and its partner Squadrone System, a designer and manufacturer of professional drones, announce the creation of a new company, Darwin Drones, to take the Eyesee inventory drone solution forward. The startup has ambitious plans and will use a forthcoming injection of capital from investors in the Auvergne-Rhône-Alpes region to scale up production of the solution and accelerate its growth in France and worldwide.

Eric Pierrel, a digital technology entrepreneur and the former head of the French Tech in the Alps-Grenoble alliance, has been appointed as the CEO of Darwin Drones. Going forward, the startup will be responsible for all aspects of the Eyesee business: software and hardware R&D, marketing, deployment, and after-sales care. It will also support existing Eyesee systems in use at the logistics warehouses of major firms such as L’Oréal, Log’S, Ikea, and Schneider Electric.

“We’re delighted to be taking over this incredible piece of technology, which won awards at CES Las Vegas and CES Asia in 2018,” said Pierrel. “We look forward to accelerating its growth in France and worldwide.”

Nicolas Odet, President of Hardis Group, will continue to support the project as a member of the Darwin Drones Advisory Board. Squadrone System, which manufactures the drone, remains onboard as hardware partner and will continue providing its expertise in the design of professional drones.

“Creating a dedicated startup to take the solution forward will accelerate Eyesee’s growth while providing continuity for existing users,” said Nicolas Odet. “We’ll also continue promoting Eyesee to our clients and prospects in Europe.”

Eyesee is now ready for full-scale production and marketing after receiving its CE marking a few months ago.

“We remain onboard to support any future changes to the drone’s design,” said Antoine Level, CEO of Squadrone System.

In 2022, Darwin Drones plans to build a network of retailers and integrators in Europe. The longer-term plan is to market the solution in the United States. In order to accelerate its growth, the startup intends to raise funds from investors in the Auvergne-Rhône-Alpes region.

Darwin Drones is a Grenoble-based company founded in 2021 to develop and market industrial logistics automation systems, including drone-based applications, and to deliver an associated line of services. The company was set up specifically to market, support, and develop software for Eyesee, an inventory drone solution for the logistics sector.

Are you considering optimizing your supply chain? Are you in the market for a real-time resource management application? Are you looking for a reliable, agile WMS that’s packed with features? Then pay us a visit at stand D77. We look forward to seeing you!

If you’re looking for an innovative inventory improvement and automation solution, come and talk to the Eyesee team at stand N97 in the drones and warehouse of the future area. And don’t miss our presentation at 1:10 pm on Tuesday, September 14, which will focus on feedback from Ludovic Doudard, Supply Chain Director at Renault.

This year’s SITL will focus on innovation, with over 550 exhibitors showcasing solutions that have the potential to change—perhaps even revolutionize—your business and the way you work. As well as discovering existing solutions, you’ll also get a chance to see transport and logistics operators demonstrating the technologies of the future. Over the course of the three-day event, you’ll learn about the latest industry news and trends, get a chance to meet new suppliers and partners, and attend sessions and workshops delivered by recognized subject-matter experts.

Dates and times

From 23 to 26 June 2020, a 100% digital version of the SITL 2020 was held. In the sanitary context of this first half of 2020, the SITL could not take place in its usual conditions. In order to preserve a moment of meetings and exchanges between the stakeholders of transport and logistics, a 100% online version was organised giving rise to meetings, virtual tours and webinars.

More than 5,100 people took part in this digital edition, with 77 speakers and nearly 500 business meetings.

Managing people, increasing productivity and agility in a context disturbed by the Covid19 pandemic, so many challenges taken up by technological innovations.

In this video:

After being awarded at the CES in Las Vegas, the autonomous inventory drone Eyesee obtains a new Innovation Award Honoree at the CES Asia. The solution will be showcased at the exhibition, to be held from June 13-15 in Shanghai.

Hardis Group announces that its solution Eyesee for carrying out inventories in logistics warehouses with the help of an autonomous drone, has just received an “Innovation Award Honoree“, in the drone category, for the third edition of CES Asia. The company will exhibit at the show with about twenty other companies, led by the French Tech Mission as well as Business France in Shanghai, on booth 4251, Hall 4N.

The main objectives of Hardis Group’s presence at CES Asia are to meet Chinese companies from the manufacturing, CPG, retail and logistics industries likely to be interested in deploying Eyesee and to recruit potential Asian distributors.

All the innovations awarded for CES Asia: http://www.cesasia.cn/events-conference/innovation-awards-listing-en/

Learn more about Eyesee: https://eyesee-drone.com/

Aware of the logistics-related opportunities offered by the physical and technical characteristics of drones, Hardis Group filed a patent in 2015 for an inventory-taking drone to automate inventories and simplify and optimize inventory management in warehouses.

The drone is equipped with sensors, enabling it to move around the warehouse autonomously, controlled by an operator. Its on-board camera identifies and captures inventory data which can be transmitted to any WMS on the market. The aim is to save time and increase productivity and safety in inventory and stock control operations.

Hardis Group recently signed an agreement with FM Logistic to test the solution at its logistics sites to check the system’s ability to meet the sector’s requirements. Innovation, which drives productivity, performance and flexibility, is a key value for FM Logistic, which has a committee of international experts dedicated to it. The aim is to imagine, design and deploy innovative solutions to improve working conditions for its employees and quality of service to its customers. So it was no surprise that the company agreed to get involved with the inventory-taking drone project.

FM Logistic opened up its warehouse in Satolas (France) to Hardis Group teams to conduct tests relating to flight conditions (site mapping, geolocation, lighting configurations, surfaces encountered by the drone, etc.) and the collection of information required for inventory-taking (label reading for example). In September, FM Logistic business teams will start testing the drone and the collection and processing of information by their tools.

Testing with FM Logistic will continue until the end of 2016.

Since its creation in 1967, FM Logistic has become an international leader in warehousing, transport and packaging. The independent family-run group is recognized as an expert in FMCG, distribution, perfume/beauty, industry and health markets.

Present in Asia, Eastern Europe, Central Europe, Western Europe and Latin America with over 20,000 employees, FM Logistic has a turnover of over a billion euros.

In addition to its international expansion, FM Logistic’s development is focused on a strong policy of innovation, while respecting the environment. The group has pioneered ‘pooling’ (shared management of transport and logistics resources), for which it has received numerous professional awards.

Environmentally responsible by design, FM Logistic is a member of the Green Freight Europe program, an initiative aimed at improving the environmental performance of freight transport in Europe.

In 2015, the company developed CityLogin, an environmentally friendly solution to address logistics requirements for the final part of the journey in European cities.

The Squadrone System team, created in 2013, launched a Kickstarter campaign for the Hexo+ project, a fully autonomous drone that follows and films the user, raising over 1.3 million dollars. In a year, the company has transitioned from concept to reality and now has over 3000 users throughout the world. Based in Grenoble, France, and San Francisco, California, Squadrone System is conquering the industrial market with its autonomous indoor and outdoor flight technologies.

Hardis Group receives the Special Jury Award of the 15th Innovation Awards at SITL (International Week of Transport and Logistics).

The jury of the SITL Innovation Awards made up of logistics and transport professionals examines about fifty entries each year.

The results were announced on Thursday, 2 April, during the last day of the exhibition: Hardis Group won the Special Jury Award for Eyesee, its inventory-taking drone.

Multilingual WordPress with WPML