Discover the benefits of drone for warehouses to increase operational efficiency in production facilities.

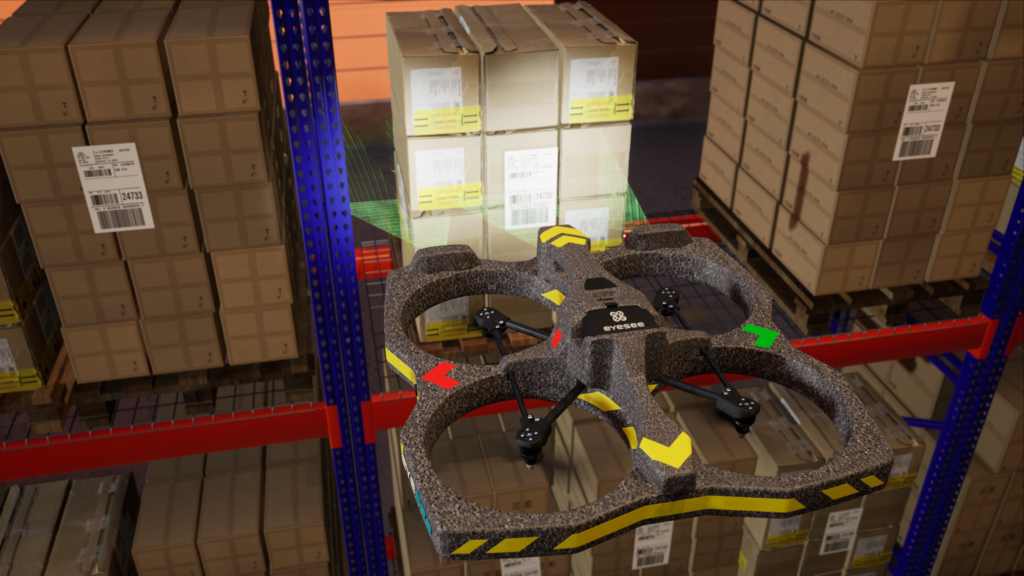

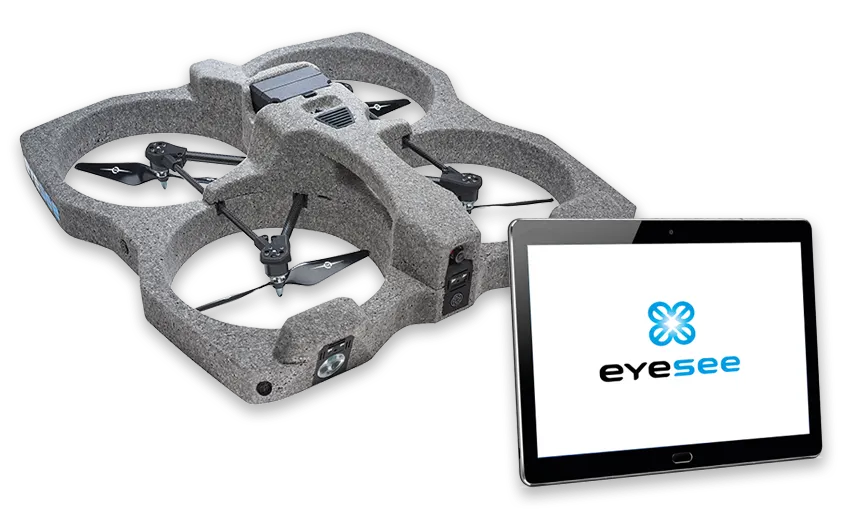

EYESEE is an inventory drone solution for logistics warehouses organized in pallets.

The solution improves inventory processes by meeting the needs of logisticians and manufacturers.

1) Reduce your resources dedicated to inventory activities

Inventory is a task that requires many resources: financial, material and human.

Furthermore, regulations require companies to take an inventory of their stock at least once a year.

Manual inventory

Inventory by drone

10 persons & more

Only 1 person to supervise the flight of the drone

The use of 1 or more scissors lifts (owned or rented)

No scissors lift

1 visit/years per location

50 locations per hour

4 visits/years per location

Up to 500 locations per hour

60 to 90 seconds per location

6 to 10 seconds per location

Thanks to the time savings generated by the use of the EYESEE Solution, companies can switch to cycle count inventory while reducing their inventory costs.

2) Make your inventory data reliable & refresh it more often

The importance of accurate inventory tracking in the warehouse should not be underestimated as errors generate direct operational costs.

It is important that all goods in the warehouse are accurately accounted for so that customer orders can be delivered on time.

The drone for warehouses EYESEE allows faster and more frequent inventories to identify potential errors.

Thanks to the different modes that can be configured, you can create inventory missions:

- blind: inventory control without theoretical quantities

- with expected: checking the differences between the theoretical stock data and the scanned locations.

- of a location (spot): control of a single location

3. Make inventory activities safer for your team

Employee safety in the warehouse is a major issue for logisticians. As soon as an operator has to access a stock at height and uses a scissor lift, he increases his risk of falling.

Thanks to the drone for warehouses, it has become possible to eliminate the use of scissors lift to control stocks, and thus significantly reduce the risks associated with working at height.

With EYESEE, only one person is needed to inventory your entire inventory. No more need for cradles. The solution also integrates many safety functions. In case of structural defects, damaged pallets or pierced packages, the operator can declare a point of interest during the flight.

4) Improve customer service

With reliable inventory counts, orders will be in compliance and shipped as expected by the customer. The impact of accurate inventory tracking is not limited to cost savings and increased efficiency.

The ability to provide optimal customer service depends on having the right products in the right place at the right time.

To achieve this goal requires frequent and accurate inventory counts.

With the EYESEE solution, identify inventory errors upstream before they become costly downstream problems.

Conclusion: Production sites benefit directly and strongly from the advantages of the drone for warehouses

In fact, finished goods warehouses adjacent to or near production sites often receive, store and reship goods in a full handling unit format. The main reason for this is that these pallets are destined for distributors or other depots where they will be broken down and shipped in packages or reassembled depending on the destination. These warehouses therefore have a proportion of racked reserves close to 100%. Most of the time, there is no picking activity, which ensures that the pallets made up, filmed and labeled with the quantity are compliant and perfectly readable by the drone. The production sites thus have all the criteria to benefit 100% from the advantages offered by EYESEE.

How much time do you spend controlling your finished goods inventory?