Warehouse Drone for logistic and industry

Thanks to this warehouse drone, identify inventory errors in advance before they become costly afterwards problems.

EYESEE flies automatically to read the barcodes of your pallet rack inventory

Why should you use a warehouse drone?

EYESEE is a tried and tested solution designed to help manufacturers and logisticians increase their operational efficiency. The solution enables inventory by automatically collecting data on stocks and locations of goods stored on pallet racks in the warehouse. The solution can be deployed in a few days and does not require any modification or addition of fixed infrastructure in your warehouses.

EYESEE solution complies with all applicable industry standards and can read all 1D & 2D barcodes. EYESEE helps 3PLs and manufacturers’ logistics services to eliminate their errors before they become downstream problems. Today, the solution is used by logistic and industry leaders in Europe and North America.

By choosing EYESEE, you are opting for a simple, efficient and pragmatic solution created by logisticians for logisticians.

The strengths of warehouse drone

Increase the efficiency of your inventory activities by 10-fold

On average, a location is scanned every 7 seconds with EYESEE versus 60 to 90 seconds manually.

Maintain activity during inventories

Manual inventories can require the warehouse to be closed for several days, EYESEE allows for the cohabitation with the staff dedicated to order preparation.

Decrease material, human and financial resources

With EYESEE, one person can do the inventory on their own. No more scissors lifts needed.

Improve Safety

With EYESEE, remove the risks caused by working at height during inventory operations.

Improve your inventories data

EYESEE solution allows you to obtain accurate stock data with photos and thus anticipate stock shortages.

Increase customer satisfaction

Thanks to your reliable stock inventories, your orders will be compliant and shipped on time.

Warehouse drone: the future of logistic

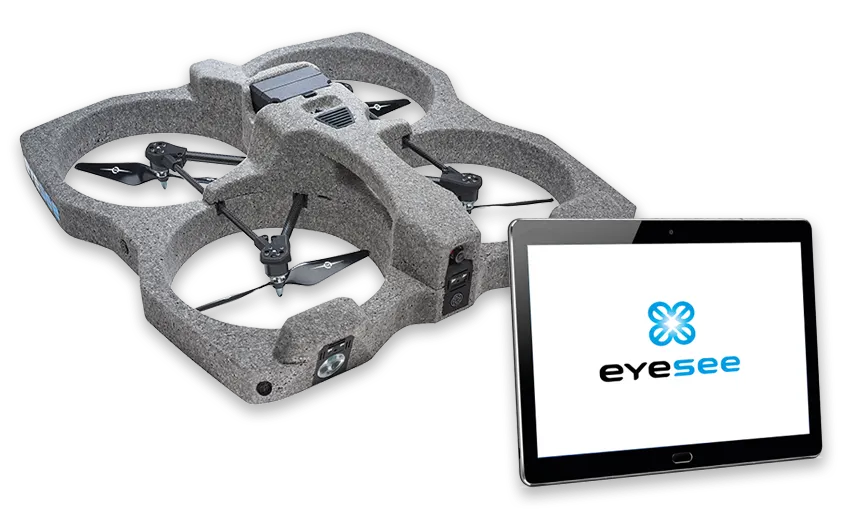

Created by two Grenoble-based companies, Hardis Group & Squadrone System, the EYESEE logistics inventory drone meets the needs of logisticians throughout the supply chain. Upstream of production and assembly units, it ensures reliability and continuity of raw materials and semifinished products. Downstream of production units, EYESEE provides reliable inventory data to ensure compliant distribution. Companies that display their rack inventories on e-commerce sites increase their sales and customer satisfaction by updating their inventory daily.

They trust us